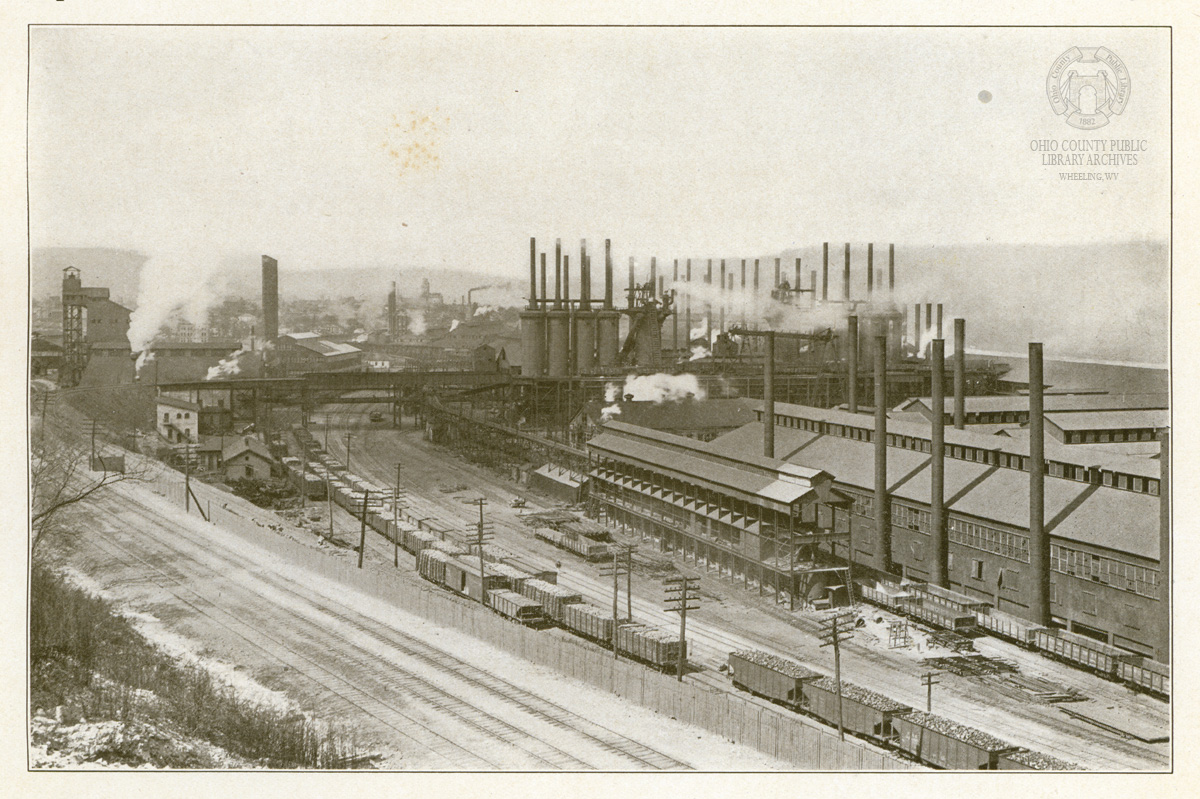

In 1852, Bailey, Woodward and Company, a newly formed group composed of 22 ironworkers and nailers, opened La Belle Iron Works just south of the Wheeling, West Virginia city limits. The four-acre location (around present-day 31st and Wood Street) was strategic, as it was near the river and the trunk line of the Baltimore and Ohio Railroad Company. The founders of the company named their mill after the French name for the Ohio River, La Belle Riviere, which means “beautiful river.” In 1859, Bailey, Woodward and Company purchased the Jefferson Iron Works in Steubenville, Ohio, adding 40 cut nail machines to the original 25 at the Wheeling site.

In 1852, Bailey, Woodward and Company, a newly formed group composed of 22 ironworkers and nailers, opened La Belle Iron Works just south of the Wheeling, West Virginia city limits. The four-acre location (around present-day 31st and Wood Street) was strategic, as it was near the river and the trunk line of the Baltimore and Ohio Railroad Company. The founders of the company named their mill after the French name for the Ohio River, La Belle Riviere, which means “beautiful river.” In 1859, Bailey, Woodward and Company purchased the Jefferson Iron Works in Steubenville, Ohio, adding 40 cut nail machines to the original 25 at the Wheeling site.

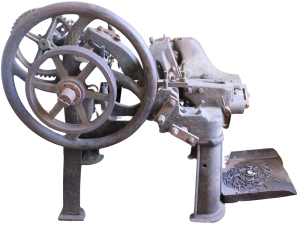

Until the last decade of the 1700s and the early 1800s, hand-wrought nails were made one by one by a blacksmith or nailer from a square iron rod. After heating the rod in a forge, the nailer would hammer all four sides of the softened end to form a point. This was the process for making nails until the automatic nail machine was invented in the 1820s. Flat metal strips are fed into the machine, while the first lever cuts a triangular strip of metal giving the desired width of the nail, the second lever holds the nail in place while the third lever forms the head of the nail. The strip of metal is then turned through 180 degrees to cut the next equal and opposite nail shape off the strip, hence the moniker “cut nails.”

Until the last decade of the 1700s and the early 1800s, hand-wrought nails were made one by one by a blacksmith or nailer from a square iron rod. After heating the rod in a forge, the nailer would hammer all four sides of the softened end to form a point. This was the process for making nails until the automatic nail machine was invented in the 1820s. Flat metal strips are fed into the machine, while the first lever cuts a triangular strip of metal giving the desired width of the nail, the second lever holds the nail in place while the third lever forms the head of the nail. The strip of metal is then turned through 180 degrees to cut the next equal and opposite nail shape off the strip, hence the moniker “cut nails.”

In 1875, the La Belle Iron Works was incorporated, and between the Jefferson works and the La Belle works employed approximately 900 workers and had a total of 167 cut nail machines in operation. It was during this time period that Wheeling began to be known as the “Nail City,” due to its dominance of the cut nail market.

Wheeling’s nail production from 1871-1873 (three million kegs) comprised nearly a quarter of the national nail production (12 million kegs). The dominance of the cut nail was to be short-lived, however, as the “Great Nail Strike” of 1885-1886 severely impacted the industry and allowed the wire nail producers to corner the market. The nailers went on strike to protest the newly adopted Bessemer process, which replaced wrought iron with steel plate as the material used to make the nails. The cut nail market would never quite recover.

By 1914, La Belle was the only company in Wheeling producing cut nails.

In 1920, La Belle Iron Works merged with the Wheeling Steel and Iron Company and the Whitaker-Glessner Company to form the Wheeling Steel Corporation. In 1967, the company merged with the Pittsburgh Steel Corporation to form Wheeling-Pittsburgh Steel Corporation. From 1967 on, La Belle was a subsidiary of Wheeling Corrugating Steel, which was a division of Wheeling-Pittsburgh Steel.

Wheeling-Pittsburgh Steel suffered during the decline of the American steel industry in the last decades of the twentieth century and filed bankruptcy twice. In 1996, the corporation sold off La Belle to D-MAC Industries, owned by Denis McMorrow. The plant was renamed Wheeling-La Belle Nail Company and operated until 2010. It was demolished in 2017.

Location

▶ 30th & Wood Streets (Closed September 30, 2010)

Images

Newspaper & Book Articles

▶ LaBelle Works in 1886 (Wheeling Daily Intelligencer Article)

▶ LaBelle Iron Works 70th Anniversary (Wheeling Register, Sunday, Feb. 5, 1922)

▶ Nail Cutting Machines in 1926 (from the book Mine to Market, 1926)

Additional Resources

Materials in the Library's Wheeling Room: (non-circulating - ask for access at reference desk)

▶ Vertical File: La Belle Nail Plant (Wheeling Room, non-circulating, ask for access at Reference Desk)

Materials in the Library's Archives: (non-circulating, view by appointment only*)

*Call 304-232-0244 or send an email to make an appointment to view archival materials.

Resources from the Library of Congress: